The Complete Guide to Clothing Manufacturing in China

When it comes to clothing manufacturing, one name dominates the global conversation: China.

As the world’s largest apparel exporter, China produces over 40% of all clothing exported globally. With manufacturing hubs like Guangzhou, Shenzhen, and Dongguan, the country offers unmatched production capacity, cost efficiency, and supply chain integration.

Whether you’re a startup launching your first collection or an established brand looking to scale production, understanding the Chinese manufacturing landscape is crucial for making informed decisions.

In this comprehensive guide, we’ll take you through everything you need to know about clothing manufacturing in China – from why it’s the global leader to navigating the manufacturing process, understanding costs, and choosing the right partner.

What you’ll learn:

- Why China is the world’s clothing manufacturing powerhouse

- Major manufacturing hubs: Guangzhou, Shenzhen, and beyond

- Complete production process from design to delivery

- Cost breakdown and pricing factors

- Quality control standards and certifications

- How to find reliable Chinese manufacturers

- Cultural considerations and communication tips

- Common pitfalls to avoid when manufacturing in China

Let’s explore the world’s largest clothing manufacturing ecosystem.

Table of Contents

Why Clothing Manufacturing in China

China’s dominance in clothing manufacturing isn’t accidental – it’s the result of decades of infrastructure development, government support, and industry specialization. Here’s why brands worldwide choose China:

1. Unmatched Production Capacity

- Scale: Over 100,000+ garment factories

- Volume: China exported $161 billion worth of clothing in 2023

- Capacity: Single factories can produce 50,000 to 500,000 pieces per month

- Flexibility: Everything from boutique runs to mass production

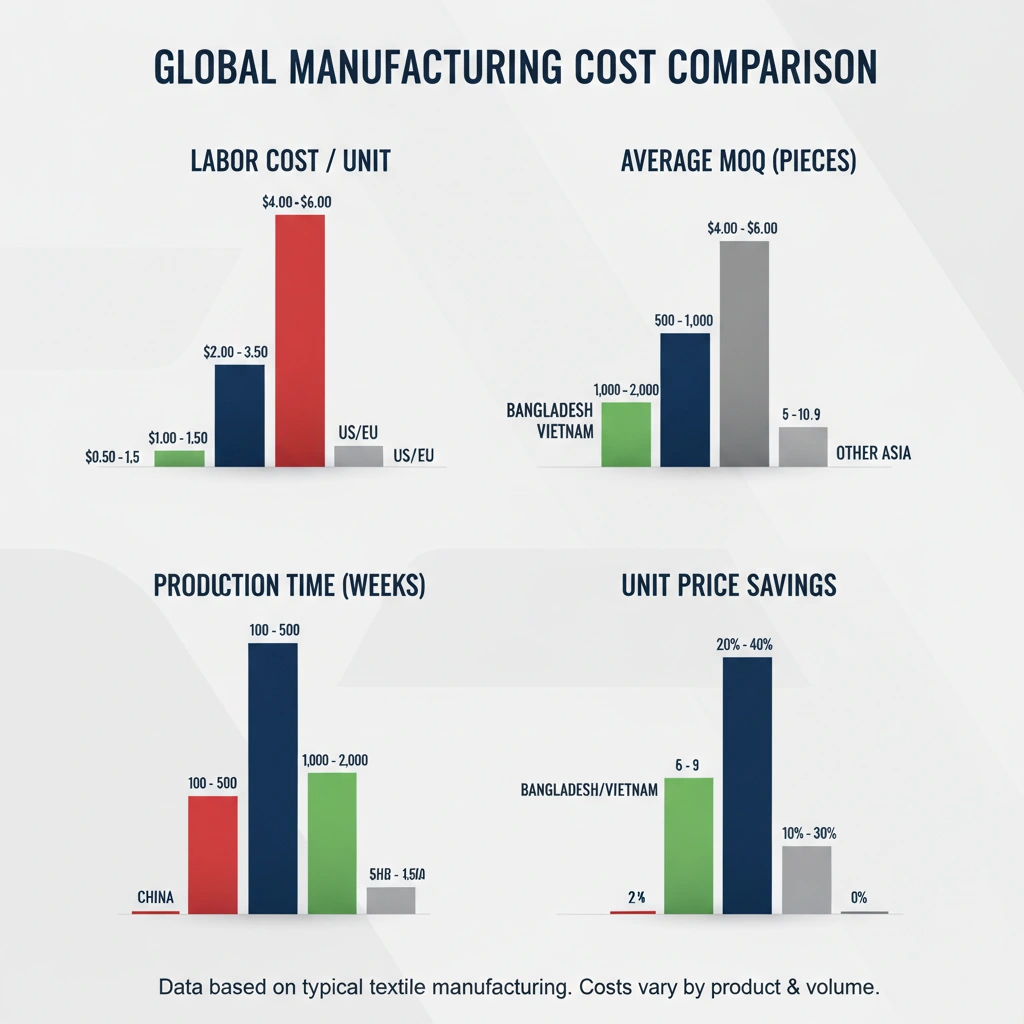

2. Cost Advantages

- Labor Cost: Competitive labor rates while maintaining quality

- Economies of Scale: Large production volumes drive down unit costs

- Supply Chain Integration: Close proximity to raw materials and accessories

- Result: 20-60% cost savings compared to manufacturing in developed countries

3. Complete Ecosystem

- Fabric Supply: China is world’s largest textile producer

- Accessories: Buttons, zippers, labels, packaging – all available domestically

- Skilled Workforce: Decades of manufacturing experience

- Technology: Advanced machinery and automation adoption

4. Infrastructure Development

- Transportation: World-class ports and logistics networks

- Industrial Zones: Specialized manufacturing clusters

- Technology Parks: Modern facilities with integrated services

- Digital Integration: Growing adoption of digital manufacturing tools

China’s Global Position in the Industry

Understanding China’s position helps you make strategic decisions about where to manufacture and how to position your brand.

Market Share and Export Data

Global Exports by Country (2023):

| Country | Export Value | Global Market Share | Key Strengths |

|---|---|---|---|

| China | $161 billion | 40.3% | Cost, Scale, Supply Chain |

| EU | $153 billion | 38.3% | Quality, Brand Value |

| Bangladesh | $47 billion | 11.8% | Labor Cost, Basic Production |

| Vietnam | $35 billion | 8.8% | Emerging Hub, Labor Cost |

| Turkey | $23 billion | 5.7% | Textile Base, EU Proximity |

| India | $16 billion | 4.0% | Labor Cost, Cotton Production |

Key Insight: China’s market share is nearly 4x that of its nearest competitor (EU combined).

Competitive Advantages

What Makes China Stand Out:

- Speed: 30-45 days from design to production start (vs 60-90 days elsewhere)

- Flexibility: Can handle 50 pieces or 50,000 pieces with minimal lead time adjustment

- Innovation: Rapid adoption of new technologies and sustainable materials

- Adaptability: Factories specialize in various market segments

Challenges to Consider

Not Everything Is Perfect:

- Rising Labor Costs: Wages increasing 8-10% annually

- Environmental Regulations: Stricter policies affecting some materials and processes

- Trade Policies: Tariffs and trade disputes in some markets

- Quality Perception: Historical stigma (improving rapidly but still exists)

Major Manufacturing Hubs

China’s manufacturing isn’t concentrated in one location – it’s spread across specialized hubs, each with unique advantages.

Guangzhou: The Southern Manufacturing Capital

Location: Guangdong Province, Southern China

Specializations:

- Fashion-forward and trend-sensitive production

- Women’s wear and dresses

- Medium to high-end fashion

- Quick response to market changes

Advantages:

- Canton Fair: World’s largest trade fair (twice yearly)

- Mature Ecosystem: Decades of manufacturing experience

- Fabric Access: Close to major fabric markets

- Logistics: Near major ports (Guangzhou, Shenzhen)

Production Capacity: 15,000+ garment factories

Shenzhen: Technology and Innovation Hub

Location: Guangdong Province, Border with Hong Kong

Specializations:

- Fast fashion and athleisure

- Performance wear and technical clothing

- Electronics-integrated fashion

- Quick turnaround production

Advantages:

- Innovation: Fast adoption of new technologies

- Hong Kong Proximity: Easy access to international resources

- Younger Workforce: Skilled, tech-savvy labor

- Export Infrastructure: Well-developed export channels

Production Capacity: 10,000+ garment factories

Dongguan: The Manufacturing City

Location: Between Guangzhou and Shenzhen

Specializations:

- Basic to mid-range fashion

- Children’s clothing

- Casual wear and t-shirts

- Mass production

Advantages:

- Lower Costs: Lower labor and facility costs than Guangzhou/Shenzhen

- High Volume: Massive production capacity

- Supply Chain: Concentrated supplier base

Production Capacity: 12,000+ garment factories

The Complete Manufacturing Process

Understanding the end-to-end process helps you plan timelines, budget accordingly, and avoid surprises.

Step 1: Design & Tech Pack Preparation (7-14 days)

What You Need:

- Design Concept: Sketches, renderings, or mood boards

- Tech Pack: Technical specification document including:

- Technical drawings (front, back, side)

- Measurements chart (all sizes)

- Fabric specifications (composition, weight, color)

- Bill of materials (BOM)

- Labels and packaging requirements

- Size grading requirements

Timeline Breakdown:

- Design concept: 2-5 days

- Tech pack creation: 5-9 days

Common Mistake: Skipping tech pack or providing incomplete specifications leads to delays and errors.

Step 2: Finding the Right Manufacturer (2-4 weeks)

Vetting Process:

- Initial Contact: Send tech pack + requirements to 10-20 manufacturers

- Quote Evaluation: Compare pricing, MOQs, and lead times

- Sample Order: Order samples from top 2-3 candidates

- Factory Visit (if feasible): Visit top 1-2 factories before committing

Evaluation Criteria:

- Capability: Can they handle your product type?

- Experience: Similar products produced before?

- Quality: Sample quality and workmanship

- Communication: Responsiveness and clarity

- Price: Competitive within market range

- MOQ: Can you work within your requirements?

Decision: Choose 1-2 primary manufacturers + 1 backup option.

Step 3: Sampling Process (10-20 days)

Sampling Stages:

1. First Sample (7-12 days)

- Factory produces initial sample based on tech pack

- You review for: Fit, quality, design accuracy

- Feedback and revisions if needed

2. Second Sample (5-8 days)

- Incorporates revision requests

- Refines fit and details

- Often includes size set (S, M, L, XL)

3. Pre-Production Sample (3-5 days)

- Final sample before bulk production

- Used for final approval

Sample Costs:

- First sample: Usually $50-200 (sometimes credited with bulk order)

- Additional samples: Typically $30-150 each

- Shipping costs: $50-200 for express delivery

Critical Point: Don’t rush this phase. Samples prevent expensive bulk production mistakes.

Step 4: Bulk Production (15-45 days)

Production Breakdown:

1. Pre-Production (3-5 days)

- Fabric procurement

- Pattern making and grading

- Cutting preparation

- Sample approval for production run

2. Production (7-25 days)

- Cutting and sewing

- Assembly and finishing

- Quality control checks

- Packaging

3. Post-Production (5-15 days)

- Final inspection

- Ironing/steaming

- Packaging and labeling

- Quality control report

Timeline Factors:

- Order Size: 100 pieces = 2-3 weeks, 5,000 pieces = 6-8 weeks

- Complexity: Basic t-shirt = 2 weeks, complex jacket = 4-6 weeks

- Season: Peak season = +1-2 weeks

Step 5: Quality Control (5-10 days)

QC Process:

1. In-Line QC (During Production)

- Random sampling during production

- Early defect detection

- Immediate corrections

2. Final Inspection (After Production)

- AQL (Acceptance Quality Limit) inspection

- Common standard: AQL 2.5 for major defects, 4.0 for minor defects

- Sample size: Typically 5-10% of total order

Inspection Checklist:

- Measurements match specifications

- Color consistency across pieces

- Stitching quality

- Labels and packaging correct

- No visible defects

Defect Classification:

| Defect Type | Critical | Major | Minor | Action |

|---|---|---|---|---|

| Wrong size | ✓ | Reject | ||

| Color variation | ✓ | Rework or reject | ||

| Loose threads | ✓ | Accept (minor) | ||

| Stains | ✓ | Reject |

Step 6: Shipping & Logistics (7-21 days)

Shipping Options:

1. Sea Freight (Economy – 15-21 days)

- Best for: Large orders (500+ pieces)

- Cost: $0.50-2.00 per kg

- Best for: Cost-sensitive orders

2. Air Freight (Express – 3-7 days)

- Best for: Urgent orders, samples, small batches

- Cost: $5.00-12.00 per kg

- Best for: Time-sensitive orders

3. Courier (Express – 2-5 days)

- Best for: Samples, urgent small orders

- Cost: $20-50 per kg

- Best for: Documents and samples

Incoterms:

- FOB (Free On Board): Factory pays costs to port

- CIF (Cost, Insurance, Freight): Factory includes shipping

- DDP (Delivered Duty Paid): Factory delivers to your door

Recommendation: Start with FOB (most common), upgrade to CIF/DDP as relationship develops.

Cost Analysis: What to Expect

Understanding costs helps you budget accurately and negotiate better.

Typical Cost Breakdown (Per Unit)

Basic T-Shirt Example (Order: 1,000 pieces):

| Cost Component | Cost Range | % of Total | Notes |

|---|---|---|---|

| Fabric | $2.00-3.50 | 35-45% | Quality dependent |

| Labor | $1.50-2.50 | 25-35% | Complexity dependent |

| Labels & Packaging | $0.30-0.80 | 5-10% | Brand dependent |

| QC & Overhead | $0.50-1.00 | 8-15% | Factory margin |

| Total Factory Cost | $4.30-9.80 | 100% |

Pricing by Order Quantity:

| Order Size | Unit Cost | Savings vs 100 pieces |

|---|---|---|

| 100 pieces | $6.50 | $0.00 (baseline) |

| 500 pieces | $5.20 | $1.30 per unit (20% savings) |

| 1,000 pieces | $4.80 | $1.70 per unit (26% savings) |

| 5,000 pieces | $4.20 | $2.30 per unit (35% savings) |

Key Insight: Volume discounts are substantial but require working capital commitment.

Hidden Costs to Consider

- Sample Costs: $100-500 initial investment

- Shipping: Ocean freight, customs duties, local delivery

- Payment Terms: Deposits (typically 30-50%)

- Currency Exchange: International transfer fees

Total Cost Example (1,000 t-shirts):

- Production: $4,800

- Samples: $300

- Shipping: $800

- Total Investment: $5,900+

Quality Control and Standards

China’s manufacturing quality has improved dramatically. Here’s what to expect and demand.

Quality Standards

Certifications to Look For:

- ISO 9001: Quality management system

- ISO 14001: Environmental management

- Oeko-Tex Standard 100: Chemical safety (fabrics)

- BSCI: Business Social Compliance Initiative

- WRAP: Worldwide Responsible Accredited Production

What These Mean for You:

- Consistent quality across production runs

- Environmental and social responsibility

- Safe materials and chemical usage

- Ethical labor practices

Quality Inspection Process

Third-Party Inspection (Recommended for First Orders):

- Companies: SGS, Intertek, Bureau Veritas

- Cost: $500-2,000 depending on order size

- Timing: After production, before shipping

- Scope: Pre-shipment inspection to AQL standards

Benefits:

- Unbiased quality assessment

- Leverage in disputes

- Verification of production quantity

- Photos and detailed report

Finding the Right Manufacturer

Choosing the right partner is critical to success. Here’s how to find them.

Where to Find Manufacturers

Trade Shows (Best for Meeting Face-to-Face):

- Canton Fair (Guangzhou): April and October

- Intertextile (Shanghai): March and September

- Magic Show: Las Vegas, February and August

Online Platforms:

- Alibaba: Verify supplier’s Gold status and trade assurance

- Made-in-China: Filter by manufacturing capability

- Global Sources: Platform connecting verified suppliers

Industry Directories:

- Guangzhou Chamber of Commerce: Local manufacturer listings

- China National Garment Association: Certified members

- Bureau Veritas: Directory of vetted suppliers

Vetting Checklist

Before Committing, Verify:

Business Essentials:

- Business license verified

- Export license

- ISO or other quality certifications

- Minimum 3 years in operation

Production Capabilities:

- Can produce your product type

- Monthly capacity meets your needs

- Equipment is modern and well-maintained

- In-house quality control

Communication:

- Responsive email/WeChat communication

- Fluent English speaker

- Clear quoting and documentation

Cultural Considerations and Communication

Successfully manufacturing in China requires understanding cultural differences.

Communication Best Practices

1. Be Specific and Clear

- Avoid vague instructions

- Provide written specifications

- Use diagrams and examples when possible

- Confirm understanding in writing after meetings

2. Build Relationships

- Visit factories when possible

- Face-to-face meetings build trust

- Respect Chinese business culture

- Invest time in relationship building

3. Understand Holidays and Schedules

- Chinese New Year (2-week factory shutdown)

- Golden Week (early October)

- Plan production around these

Common Misunderstandings

Cultural Differences to Avoid:

- “Yes” Doesn’t Always Mean Yes: In Chinese culture, saying “yes” can mean “I hear you,” not agreement

- Direct vs. Indirect Communication: Chinese culture values indirect communication

- Time Perception: “Soon” may mean different things – ask for specific dates

- Contract Negotiation: More flexible than written contracts – document everything

How Algo Bert Fashion Can Help

Located in the heart of Guangzhou, Algo Bert Fashion offers the ideal gateway to China’s manufacturing ecosystem.

Our Guangzhou Advantage

Strategic Location:

- Canton Fair Access: Minutes from the world’s largest trade fair

- Fabric Markets: Immediate access to major textile markets

- Transportation Hub: Near Guangzhou Port

- Supplier Network: Decades of relationships with suppliers

Manufacturing Capabilities:

- Flexible Production: Low MOQ options (50-100 pieces) for startups

- Diverse Product Range: From basic t-shirts to complex outerwear

- In-House Quality Control: Rigorous QC at every stage

- Sample Production: Fast turnaround with reasonable pricing

Services for International Brands:

- Tech Pack Creation: If you don’t have technical drawings

- Sourcing Assistance: Finding fabrics and materials

- Design Consulting: Refining concepts for manufacturability

- Sample Coordination: Managing sampling process

- Production Management: Full oversight from start to finish

- Quality Assurance: AQL inspection and detailed reporting

- Shipping Logistics: Arranging export documentation and freight

Learn more about our manufacturing services →

FAQ: Questions About Manufacturing in China

What is the typical production time for clothing in China?

Production time varies: Basic t-shirts and casual wear typically take 2-3 weeks for 1,000 pieces; More complex items like jackets take 3-5 weeks for 1,000 pieces; Large orders (5,000+ pieces) may take 4-8 weeks. Sampling adds 10-20 days before production. Peak seasons can add 1-2 weeks.

How much does it cost to manufacture clothing in China?

For basic t-shirts, expect 8-15 per unit; For outerwear like jackets, expect $15-25 per unit. These costs include fabric, labor, packaging, and QC. Shipping and duties are additional.

What is the minimum order quantity (MOQ) in China?

MOQs vary: Large factories often require 500-5,000 pieces per color; Medium factories typically require 100-1,000 pieces; Small workshops may accept 30-100 pieces. Some low MOQ manufacturers offer 10-50 pieces for startups.

Which Chinese city is best for clothing manufacturing?

Guangzhou is best for fashion-forward, women’s wear, and mid-to-high-end fashion; Shenzhen excels in fast fashion and athleisure; Dongguan is ideal for basic casual wear and mass production; Changzhou dominates in down jackets and outerwear.

Is manufacturing in China ethical and sustainable?

Many factories hold certifications like BSCI, WRAP, and Oeko-Tex. Environmental regulations are stricter, and factories are investing in sustainable materials. However, practices vary – vet manufacturers carefully and request certifications.

How do I protect my intellectual property when manufacturing in China?

Use written contracts with clear IP ownership clauses; Register trademarks before sharing with manufacturers; Use NDAs for sensitive information; Share designs selectively; Consider Chinese trademark registration for additional protection.

What are the best shipping options from China?

Sea freight (15-21 days) is most cost-effective for large orders; Air freight (3-7 days) balances speed and cost for medium orders; Express courier (2-5 days) is fastest for samples and urgent small orders.

Should I visit the factory in China?

Factory visits are highly recommended, especially for first-time production runs and large orders. Benefits include building trust, verifying capabilities, assessing working conditions, and understanding production capacity.

What payment terms are typical for Chinese manufacturers?

Most common is 30% deposit, balance before shipping (T/T); Variations include 50% deposit for new customers; Payment methods include bank wire transfers and Alibaba Trade Assurance for smaller orders.

Conclusion

China’s dominance in clothing manufacturing isn’t accidental – it’s the result of unmatched production capacity, integrated supply chains, cost efficiency, and continuous improvement.

Key takeaways:

- China produces 40%+ of world’s clothing exports

- Major hubs (Guangzhou, Shenzhen, Dongguan) offer specialized capabilities

- Complete process takes 6-8 weeks from design to delivery

- Costs are 30-50% lower than developed countries

- Quality standards have improved significantly with certifications

- Finding the right partner is critical to success

Ready to start your manufacturing journey in China?

Why Algo Bert Fashion?

- ✅ Guangzhou-based with deep manufacturing expertise

- ✅ Low MOQ options for startups (50-100 pieces)

- ✅ Quality control and AQL inspection included

- ✅ End-to-end support from design to delivery

- ✅ Transparent pricing with no hidden fees

- ✅ English-speaking team for clear communication

Get Started in 3 Simple Steps:

- [Share Your Designs] – Send us your concepts, tech packs, or product ideas

- [Receive Your Quote] – Get detailed pricing and timeline within 24-48 hours

- [Begin Production] – Start with samples, scale as you grow

Related Posts: