Guangzhou vs Shenzhen: Which is Better for Clothing Manufacturing?

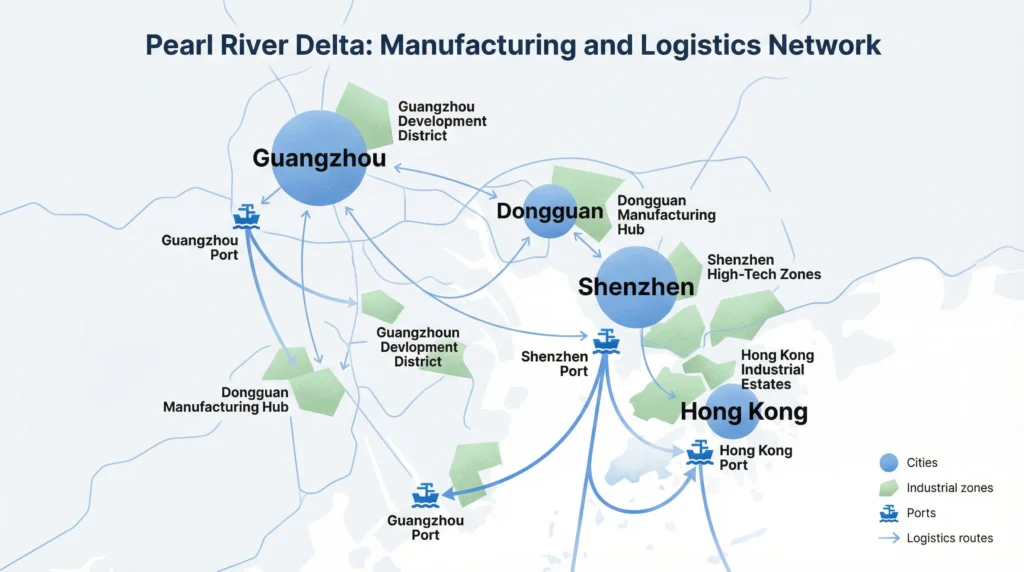

If you’re sourcing clothing from China, you’ve likely encountered the same question many fashion entrepreneurs face: should you work with manufacturers in Guangzhou or Shenzhen? Both cities sit within the Pearl River Delta, one of the world’s most concentrated manufacturing regions, and both host thousands of clothing factories serving international brands. Yet the two cities offer distinctly different advantages, and understanding these differences can significantly impact your sourcing success.

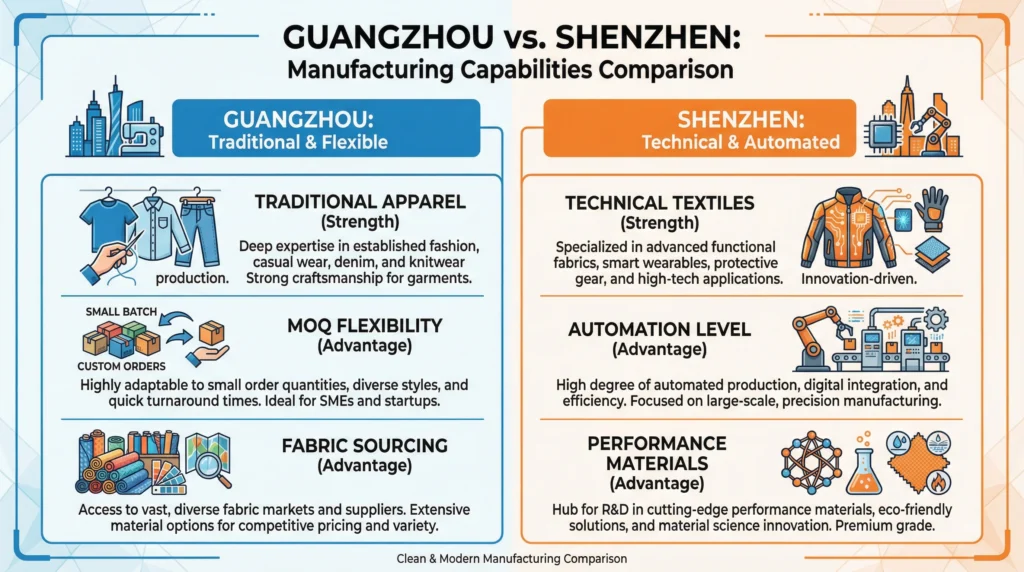

The reality is that neither city is universally “better” for clothing manufacturing. The right choice depends on your specific priorities—whether you prioritize fabric sourcing, technology integration, minimum order quantities, or something else entirely. Guangzhou excels in traditional apparel manufacturing with deep textile industry roots, while Shenzhen has emerged as a hub for technical textiles and fashion-forward production. Both cities can deliver excellent results; the key is matching your needs with each location’s strengths.

In this detailed comparison, we’ll examine Guangzhou and Shenzhen across the factors that matter most to fashion brands: manufacturing capabilities, cost structures, fabric and material access, logistics and shipping, and ideal use cases. By the end, you’ll have a clear framework for deciding which city—and which type of manufacturer—best fits your business requirements.

Table of Contents

Geographic and Industry Overview

Understanding the historical development of each city’s manufacturing ecosystem provides essential context for your sourcing decisions. Guangzhou and Shenzhen may appear similar on a map, but their industries have evolved along different paths over the past four decades.

Guangzhou’s manufacturing heritage stretches back centuries. As one of China’s oldest trading cities and the terminus of the ancient Maritime Silk Road, Guangzhou developed deep expertise in textiles and apparel long before modern manufacturing arrived. The city’s industrial zones, particularly in districts like Haizhu (home to the Zhongda Textile Market), Panyu, and Shiqi, reflect this long history. Guangzhou’s strength lies in traditional apparel manufacturing—woven garments, denim, cotton basics, and the full supply chain from raw fibers to finished goods. The city hosts numerous trading companies that facilitate exports, making it accessible for international buyers who may be new to Chinese manufacturing.

Shenzhen’s manufacturing story began in 1980 when it became China’s first Special Economic Zone. Unlike Guangzhou’s gradual industrial evolution, Shenzhen was essentially built from scratch as a manufacturing and technology hub. This origin has shaped its manufacturing character: facilities tend to be newer, more automated, and more technology-focused. While Shenzhen produces all apparel categories, it has particular strength in technical textiles, sportswear, outdoor gear, and fashion brands requiring advanced material properties. The city’s proximity to Hong Kong also makes it convenient for buyers traveling from international hubs.

The geographic proximity between these cities—approximately 100 kilometers—means they’re more complementary than competitive. Many brands work with manufacturers in both locations, selecting different factories for different product lines. For your sourcing strategy, consider these cities as part of a single manufacturing ecosystem rather than mutually exclusive options.

Manufacturing Capabilities Comparison

Manufacturing capabilities vary not just between cities but within each location. However, certain patterns emerge that can guide your supplier search.

Guangzhou manufacturing strengths center on traditional apparel production. The city excels in woven garments, shirts, trousers, and denim products where construction expertise and sewing skills matter most. Factories in Guangzhou often specialize in specific garment types rather than trying to produce everything, creating a network of specialists you can tap for different products. The workforce includes many skilled tailors and seamstresses with decades of experience in traditional construction methods. Guangzhou also hosts extensive trimming and accessory suppliers, making it easy to source buttons, zippers, labels, and other components locally.

Shenzhen manufacturing strengths lean toward technical apparel and performance fabrics. The city’s emphasis on technology extends to textiles—you’ll find more manufacturers working with moisture-wicking materials, compression fabrics, and technical blends. Production facilities often feature more modern equipment, including automated cutting systems and advanced sewing technology. This makes Shenzhen particularly suitable for sportswear, outdoor apparel, activewear, and brands prioritizing technical performance features. The workforce tends to be younger and more comfortable with technology-driven production methods.

Quality considerations depend heavily on specific factories rather than city-level generalizations. Both Guangzhou and Shenzhen host manufacturers ranging from world-class facilities serving major international brands to small workshops with limited capabilities. The key differentiator is often factory age and management quality rather than city location. When evaluating manufacturers, focus on their specific capabilities, certifications, and track record rather than making assumptions based solely on their location.

Cost Structure and MOQ Differences

Cost considerations drive many sourcing decisions, and understanding how Guangzhou and Shenzhen differ in pricing and minimum order requirements helps you budget realistically.

Guangzhou cost structure tends to favor brands seeking value in traditional manufacturing. The mature supply chain and intense competition among established factories often result in competitive pricing for basic to mid-range apparel. Lower labor costs compared to Shenzhen—reflecting the different economic development levels—can translate to savings on labor-intensive garment construction. However, rising costs across the Pearl River Delta have narrowed historical price gaps between cities. Guangzhou typically offers more flexibility on minimum order quantities, with many factories willing to accommodate 200-500 unit orders for emerging brands.

Shenzhen cost structure reflects its more technology-focused manufacturing base. While labor costs may be slightly higher, the productivity advantages of more automated facilities can offset this difference. Manufacturers in Shenzhen often target higher MOQs—typically 500-1,000 units minimum—reflecting their orientation toward established brands and larger production runs. The city tends to attract brands willing to pay premium prices for technical capabilities, consistent quality, and advanced production methods. For products requiring these attributes, Shenzhen pricing may represent better value despite higher base costs.

Negotiation realities matter more than published price lists. Both cities offer room for negotiation, particularly for ongoing orders and relationships. Building volume over time and demonstrating reliability as a customer typically unlocks better pricing regardless of location. Consider total cost of ownership—including potential quality issues, communication costs, and logistics—rather than focusing solely on unit price. Sometimes paying slightly more for a more reliable manufacturer saves money overall.

Fabric and Material Sourcing

Access to materials often determines what’s possible in garment production, and Guangzhou and Shenzhen offer different sourcing environments.

Guangzhou’s fabric sourcing advantages stem from its role as China’s textile hub. The Zhongda Textile Market in Haizhu District alone covers over 200,000 square meters with thousands of vendors selling every fabric type imaginable. This concentration means you can source, compare, and purchase materials directly from mills and traders, often seeing physical samples before committing to bulk orders. Guangzhou particularly excels in cotton, denim, and traditional woven fabrics where Chinese mills have developed deep expertise. The ability to source trims, buttons, zippers, and other components nearby reduces lead times and shipping costs for materials.

Shenzhen’s material sourcing tends toward technical and performance textiles. While not as extensive as Guangzhou’s fabric markets, Shenzhen offers strong access to mills producing performance fabrics, synthetic blends, and technical textiles. The city’s technology orientation means more suppliers focus on material innovation rather than commodity fabrics. For brands prioritizing performance features, moisture management, or technical material properties, Shenzhen’s supplier network may offer more relevant options. The city also hosts many trading companies specializing in imported luxury fabrics for brands seeking European materials.

Hybrid sourcing strategies work well for brands with diverse product lines. Many successful fashion companies source basic fabrics in Guangzhou while purchasing technical materials through Shenzhen suppliers. This approach leverages each city’s strengths while potentially reducing overall material costs. Consider whether your product line benefits from such a strategy, and be prepared to work with multiple suppliers to optimize material sourcing.

Logistics and Shipping Considerations

Getting products from factory to your warehouse involves logistics that differ between manufacturing locations.

Guangzhou logistics infrastructure includes the city’s traditional role as a trading hub. The Port of Guangzhou handles significant container traffic, while the nearby Nansha Port has expanded capacity for larger vessels. Guangzhou Baiyun International Airport serves air freight needs, and multiple express services offer daily connections to global destinations. The city’s established trading ecosystem means numerous freight forwarders, customs brokers, and logistics providers compete for your business. For brands targeting markets in Southeast Asia, Guangzhou’s geographic position offers relatively convenient access.

Shenzhen logistics advantages stem from the city’s modern infrastructure and proximity to Hong Kong. The Port of Shenzhen (including Yantian and Shekou terminals) ranks among the world’s busiest and offers excellent global connectivity. Shenzhen’s airport handles substantial air freight, and the Hong Kong International Airport—only about an hour away—provides additional options for time-sensitive shipments. The city’s concentration of export-oriented manufacturing means logistics providers have developed efficient processes for handling international shipments.

Shipping cost considerations depend on your volume, destination, and timeline. Both cities offer competitive freight rates due to the high volume of exports from the Pearl River Delta. For most brands, the logistics cost difference between Guangzhou and Shenzhen manufacturing is minimal and unlikely to drive sourcing decisions. Focus instead on the total landed cost including product price, shipping, and any quality risks that might require re-shipments.

Which City Should You Choose?

Given all these factors, how do you decide between Guangzhou and Shenzhen clothing manufacturing? The answer depends on your specific product and business priorities.

Choose Guangzhou when: You’re producing traditional apparel like woven shirts, denim, cotton basics, or garments where construction quality and fabric selection are paramount. Your priority is fabric sourcing and material options. You prefer lower minimum order quantities and more flexibility for emerging brands. Your budget targets mid-range pricing for quality production.

Choose Shenzhen when: Your products require technical textiles, performance fabrics, or advanced material properties. You’re producing sportswear, activewear, or outdoor apparel. Your priority is modern production equipment and technology integration. You’re an established brand with larger order quantities and consistent production needs.

Consider both cities when: Your product line spans multiple categories with different manufacturing requirements. You have capacity to manage relationships with multiple suppliers. Your sourcing strategy benefits from having backup options in different locations. You’re still exploring manufacturing options and want to compare capabilities firsthand.

The good news is that geographic proximity between Guangzhou and Shenzhen means you can potentially visit both cities during a single sourcing trip. Many international buyers fly into Hong Kong, visit manufacturers in both cities, and return having developed relationships in both locations. This flexibility is a significant advantage of the Pearl River Delta manufacturing ecosystem.

How Algo Bert Fashion Can Help

Navigating manufacturing options between Guangzhou and Shenzhen requires local expertise and established relationships. At Algo Bert Fashion, we’ve developed deep knowledge of manufacturing capabilities across both cities, helping fashion brands identify the right manufacturing partners for their specific needs.

Our team understands the strengths of each manufacturing location and can help match your product requirements with factories that have proven capabilities. Whether your priorities lie with Guangzhou’s traditional manufacturing expertise or Shenzhen’s technical capabilities, we can identify suppliers who meet your quality standards and business requirements. Beyond initial matching, we provide ongoing support including quality control, production monitoring, and logistics coordination to ensure successful manufacturing partnerships.

Our Services:

- Manufacturing location strategy based on your product requirements

- Supplier identification and verification in both Guangzhou and Shenzhen

- Sample development and production coordination

- Quality control and factory auditing

- Supply chain optimization across manufacturing locations

Explore our manufacturing services

FAQ: Guangzhou and Shenzhen Manufacturing

Is Guangzhou or Shenzhen better for small clothing brands?

Both cities accommodate small brands, but Guangzhou generally offers more flexibility on minimum order quantities and more entry-level manufacturing options. The extensive fabric sourcing in Guangzhou also benefits small brands seeking affordable materials for limited production runs. Shenzhen tends toward larger-scale operations, though small-brand-friendly factories do exist.

Can I visit factories in both cities during one trip?

Yes, the cities are approximately 100 kilometers apart, making it practical to visit both during a single sourcing trip. Many buyers fly into Hong Kong International Airport, which offers convenient access to both cities. A well-planned itinerary can include factory visits in both locations over 3-5 days.

Does manufacturing quality differ between the cities?

Quality depends more on individual factory capabilities than city-level generalizations. Both Guangzhou and Shenzhen host world-class manufacturers and less reliable options. The difference lies in typical factory characteristics—Guangzhou manufacturers often emphasize traditional craftsmanship while Shenzhen factories typically feature more modern equipment.

Which city is better for denim manufacturing?

Guangzhou has stronger traditional denim manufacturing heritage, with numerous factories specializing in denim development and production. The fabric sourcing advantages in Guangzhou also benefit denim production, where fabric quality significantly impacts final product value.

How do I decide which city is right for my products?

Start by identifying your product requirements: material types, construction complexity, technical features, and order quantities. Match these requirements with each city’s strengths. When possible, obtain quotes from manufacturers in both locations and compare not just pricing but communication, capabilities, and responsiveness. Your first product development often reveals which manufacturing ecosystem works best for your specific needs.

Conclusion

The Guangzhou vs Shenzhen debate ultimately misses the point: both cities offer excellent manufacturing options within the broader Pearl River Delta ecosystem. Your decision should reflect your product requirements, business priorities, and growth stage rather than any absolute superiority of one location over another.

For traditional apparel with fabric variety, competitive pricing, and lower MOQs, Guangzhou manufacturing often provides the best fit. For technical apparel, modern production capabilities, and larger order volumes, Shenzhen may be the stronger choice. Many successful brands leverage both cities, selecting the most appropriate manufacturing location for each product category.

Whatever your manufacturing location, the keys to success remain consistent: thorough supplier verification, clear communication, detailed documentation, and relationship building over time. With patience and the right approach, you can develop manufacturing partnerships that support your brand’s growth—whether those partners are in Guangzhou, Shenzhen, or both.

Ready to explore your manufacturing options? Let Algo Bert Fashion help you navigate sourcing between Guangzhou and Shenzhen, connecting you with manufacturers that match your specific requirements and business goals.

Contact our team to discuss your manufacturing needs or request a free sample

Related Posts: