How to Find Reliable Clothing Manufacturers in Guangzhou: The Complete Guide for Fashion Brands

Dreaming of launching your fashion brand but feeling overwhelmed by the prospect of finding trustworthy clothing manufacturers in Guangzhou? You’re not alone. Every year, thousands of entrepreneurs venture into China’s manufacturing landscape, hoping to transform their design concepts into high-quality products. Yet, the journey from sketch to shipped goods is fraught with challenges—language barriers, quality inconsistencies, communication gaps, and the ever-present risk of encountering unreliable suppliers.

Guangzhou has earned its reputation as one of China’s manufacturing powerhouses, housing thousands of clothing factories across numerous industrial zones. While this concentration offers incredible opportunities for fashion brands, it also means navigating a complex ecosystem where not all manufacturers deliver the same level of quality, reliability, or professionalism. The difference between a successful manufacturing partnership and a costly nightmare often comes down to how thoroughly you vet potential suppliers before committing to a production run.

In this comprehensive guide, we’ll walk you through everything you need to know about finding and working with reliable clothing manufacturers in Guangzhou—from initial research methods and verification techniques to building lasting partnerships that help your brand grow. Whether you’re launching your first collection or looking to expand your existing production capabilities, this guide will equip you with the knowledge and tools to make informed decisions.

What you’ll learn:

- How to research and identify potential clothing manufacturers in Guangzhou

- Essential verification steps to separate reliable suppliers from risky options

- Key questions to ask during supplier evaluation

- Red flags that should raise immediate concerns

- How to build and maintain strong manufacturer relationships

- Practical tips for first-time importers

Table of Contents

Understanding Guangzhou’s Manufacturing Landscape

Guangzhou, the capital of Guangdong Province, has been a trading hub for centuries. Today, it’s home to some of China’s most developed industrial zones, particularly for textiles and apparel. The city and surrounding regions— including Shenzhen, Dongguan, and the Pearl River Delta—account for a significant portion of global clothing production. Understanding this landscape is crucial for anyone serious about sourcing from China.

The Guangzhou apparel industry operates through several key industrial zones, each with its own specializations. The Zhongda Textile Market in the Haizhu District serves as a major hub for fabric sourcing, while areas like Panyu and Nansha host large-scale manufacturing facilities. These zones have developed over decades, creating ecosystems where design, production, and logistics operate in close proximity. This concentration means you can often source fabrics, trims, and finished goods within a relatively small geographic area, streamlining your supply chain.

What makes Guangzhou particularly attractive for fashion brands is the depth of its manufacturing ecosystem. Beyond large factories, you’ll find specialized workshops capable of handling everything from delicate embroidery to complex printing techniques. This specialization means you can often find manufacturers who excel in your specific product category, whether you’re producing activewear, denim, formal wear, or casual apparel. The competition among suppliers also tends to drive better pricing and more flexible minimum order quantities than you might find in less developed manufacturing regions.

However, this density also means you’ll encounter a wide range of manufacturers—from world-class facilities serving major international brands to small workshops with limited capabilities and inconsistent quality. The key to success lies not in avoiding Guangzhou’s manufacturing ecosystem but in developing the skills to navigate it effectively. Understanding the landscape helps you target your search appropriately and set realistic expectations for what different types of manufacturers can deliver.

Research Methods for Finding Suppliers

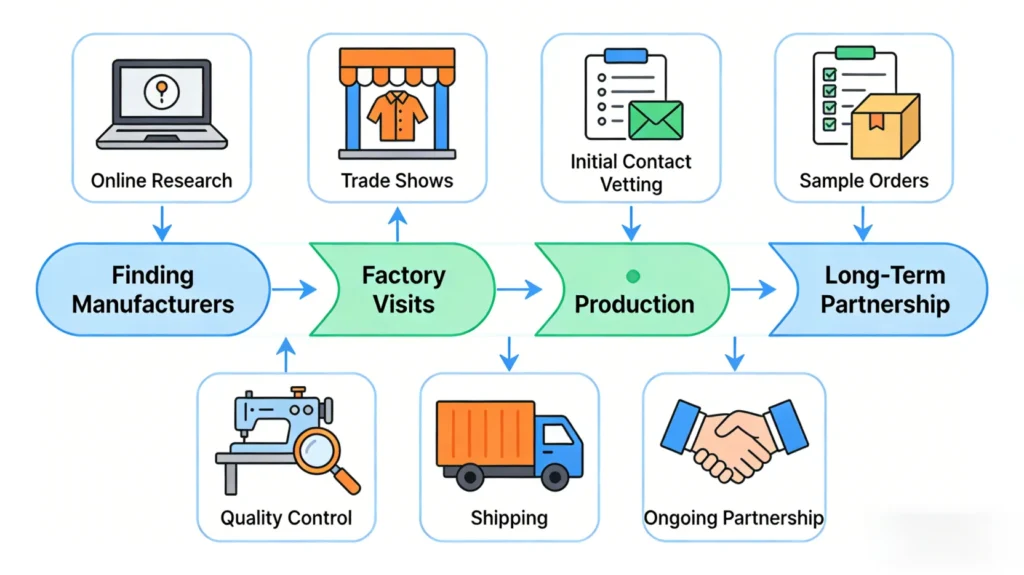

Before you book that flight to Guangzhou, invest time in thorough preliminary research. The suppliers you find online will form the basis of your initial outreach, and the quality of this research directly impacts how efficiently you can identify promising manufacturing partners.

Online directories and platforms provide the most accessible starting point for your search. Alibaba remains the largest B2B platform, offering thousands of clothing manufacturers in the Guangzhou area. When using these platforms, look beyond the basic search results—dive into company profiles, verify their years in business, examine their transaction history, and carefully review feedback from previous buyers. Platforms like Made-in-China.com and Global Sources also serve the Guangzhou market and may offer access to different supplier bases. Remember that any supplier found through these platforms should still undergo thorough verification; a listing doesn’t guarantee reliability.

Industry trade shows offer invaluable opportunities to meet manufacturers face-to-face and assess their capabilities directly. The China Import and Export Fair (Canton Fair), held twice annually in Guangzhou, is the world’s largest trade fair and includes extensive apparel and textile sections. While the Canton Fair primarily targets large-scale buyers, smaller regional exhibitions like the Guangzhou International Textile and Garment Fair may be more accessible for emerging brands. At trade shows, you can examine product samples, discuss your requirements directly, and get a sense of each company’s professionalism and communication style. Many successful brand-manufacturer relationships begin with connections made at these events.

Professional networks and industry associations can provide introductions to vetted manufacturers. Facebook groups, Reddit communities, and LinkedIn networks focused on fashion entrepreneurship and apparel manufacturing often feature discussions about supplier experiences. While individual anecdotes shouldn’t replace your own verification, they can help you identify manufacturers with strong reputations or warn you about suppliers to avoid. Industry associations like the China Chamber of Commerce for Import and Export of Machinery and Electronic Products (CCCME) can also provide directories of member companies, though membership alone doesn’t guarantee quality.

Direct factory visits remain the gold standard for supplier evaluation, even if you can’t visit in person initially. If travel isn’t immediately feasible, consider hiring a sourcing agent or quality control company based in Guangzhou to conduct factory audits. These professionals can assess manufacturing capabilities, verify business credentials, and provide detailed reports on facility conditions, production capacity, and management quality. Services like QIMA, Bureau Veritas, and local Chinese agencies offer these verification services at various price points, often starting from a few hundred dollars for a basic audit.

Essential Verification Steps

Once you’ve identified potential clothing manufacturers in Guangzhou, rigorous verification becomes essential. Many importers have learned this lesson the hard way—discovering problems only after payments have been made and production has begun. A systematic verification process protects your investment and significantly reduces the risk of manufacturing failures.

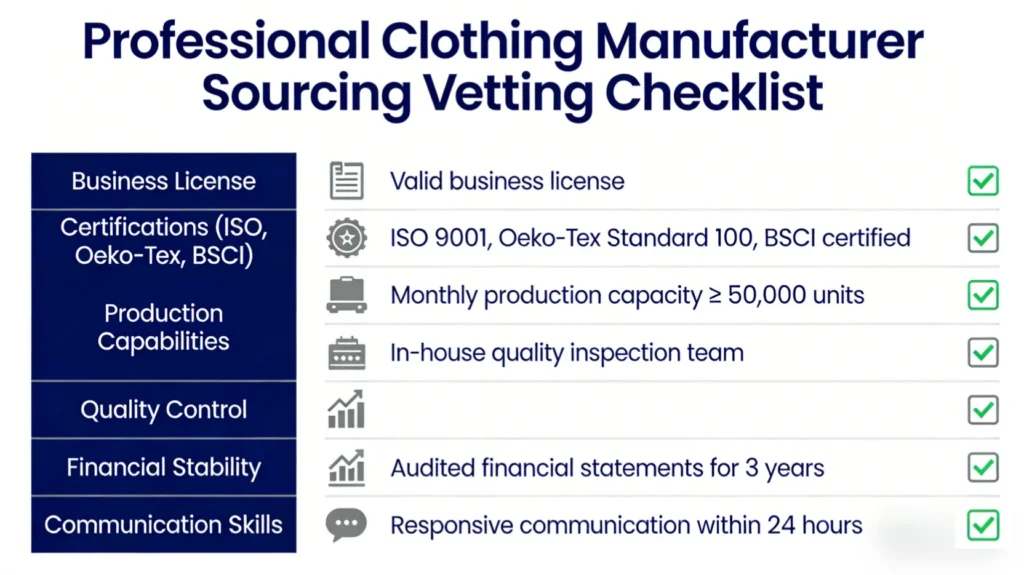

Business license verification forms the foundation of supplier verification. Every legitimate Chinese manufacturer must hold a valid business license (营业执照), which you can verify through the National Enterprise Credit Information Publicity System (http://www.gsxt.gov.cn). This verification reveals the company’s official registration details, including legal representative, registered capital, business scope, and operational status. Pay particular attention to the business scope—ensure the license explicitly includes apparel manufacturing or processing if that’s what you’re ordering. A company registered only for trading, without manufacturing capabilities, may be a middleman markup rather than a direct factory.

Certifications and quality management systems provide additional confidence in a manufacturer’s capabilities. While certification doesn’t guarantee perfect production, it indicates a baseline commitment to quality management. Look for ISO 9001 certification for quality management systems, OEKO-TEX certification for textile safety standards, and industry-specific certifications like BSCI (Business Social Compliance Initiative) or WRAP (Worldwide Responsible Accredited Production) for social compliance. Be aware that some manufacturers obtain certifications specifically to win orders without maintaining the practices those certifications represent. Treat certifications as one data point among many rather than definitive proof of quality.

Factory capability assessment determines whether a manufacturer can actually produce what you’re ordering. This assessment includes evaluating their production equipment, technical capabilities, workforce size, and facility conditions. Ask about their experience with your specific product type—manufacturing activewear requires different equipment and skills than producing formal wear or denim. Request samples of similar products they’ve produced for other clients, and don’t hesitate to ask for references from current or past customers. A reliable manufacturer should be able to provide this information and understand why you’re asking.

Financial stability indicators help assess the long-term viability of potential manufacturing partners. While you likely can’t access full financial statements, you can look for indicators of stability: years in business (with the same registration), consistent presence at trade shows, growth in transaction volume on B2B platforms, and positive long-term feedback from multiple buyers. Manufacturers experiencing financial difficulties may take longer to respond, miss deadlines, or worse—disappear entirely with your payment. Trust your instincts; if something seems unstable, it probably is.

Key Questions to Ask Potential Manufacturers

Effective communication reveals as much about a manufacturer as their marketing materials. The questions you ask—and how they respond—provide valuable insights into their operations, capabilities, and business practices.

Production capability questions establish whether a manufacturer can handle your specific requirements. Ask about their monthly production capacity and whether they typically work with order sizes similar to yours. Inquire about their experience with your product category and request examples of similar products they’ve manufactured. Discuss their equipment capabilities, particularly for any specialized processes your products require. Ask about their typical lead times from sample approval to final delivery, and find out what factors might affect those timelines. The best manufacturers will ask clarifying questions about your requirements, demonstrating genuine interest in understanding your needs rather than simply processing orders.

Quality control questions reveal how seriously a manufacturer takes product consistency. Ask about their quality management system—do they have dedicated quality control staff, inspection points during production, and documented procedures for handling defects? Request information about their defect rate and how they handle quality issues when they occur. Discuss their policy for pre-shipment inspection and whether they’ll accommodate third-party quality control services you arrange. Manufacturers who are defensive about quality questions or unable to provide clear answers about their QC processes should raise concerns.

Communication and language questions directly impact your ability to work effectively with a manufacturer. Ask about the English proficiency of your primary contact person and whether you’ll be communicating directly with production staff or through sales representatives. Discuss their preferred communication channels and typical response times. Test their responsiveness during your evaluation process—slow or unclear communication now often indicates bigger problems later. Consider whether language barriers might cause costly misunderstandings in technical specifications or quality requirements.

Business practice questions help you understand how a manufacturer operates as a business partner. Ask about their payment terms and whether they’re willing to offer trade assurance or escrow arrangements. Discuss their policy for handling design confidentiality and intellectual property protection. Inquire about their approach to resolving disputes and whether they’ve had any significant issues with previous international clients. Ask for references from clients in your market or with similar order sizes. The most professional manufacturers will provide this information readily and understand why you’re asking.

Red Flags to Watch Out For

Learning to identify warning signs early can save you from devastating manufacturing failures. While not every red flag indicates a scam, multiple concerns should prompt you to look elsewhere for clothing manufacturers in Guangzhou.

Unrealistic pricing stands out as perhaps the most common warning sign. If a manufacturer’s quote is significantly below market rates—often 30% or more lower than other quotes—question why. Legitimate manufacturers need to cover material costs, labor, overhead, and reasonable profit margins. Prices that seem too good to be true typically mean corners will be cut: inferior materials, rushed production, or skipped quality control steps. This doesn’t mean you should always choose the most expensive option, but beware of quotes that deviate dramatically from market norms.

Reluctance to provide samples or factory visits should immediately raise your guard. Legitimate manufacturers expect to prove their capabilities through product samples and facility tours. If a supplier resists sending samples, charges excessive sample fees, or creates obstacles to factory visits, they may be hiding something. This resistance could indicate they don’t actually manufacture the products they claim to, their quality doesn’t match their descriptions, or their facility conditions would raise concerns. Sample fees are reasonable, but unreasonable charges or excessive delays in providing samples warrant concern.

Inconsistent or evasive communication signals potential problems with management and operations. Watch for responses that don’t address your actual questions, frequent changes in contact personnel, or extended response times that suggest disorganization. Pay attention to whether communication style and knowledge level remain consistent across interactions—if different contacts provide conflicting information, internal communication may be poor. Language barriers can cause communication challenges, but professional manufacturers work to overcome these rather than using them as excuses for unclear responses.

Pressure tactics and unusual payment requests often indicate fraudulent operations. Be wary of manufacturers who pressure you to make quick decisions, offer “limited-time” discounts that expire immediately, or request unusual payment arrangements. Legitimate suppliers understand that international buyers need time for due diligence and typically offer standard payment terms like 30% deposit with balance before shipment. Requests for full payment upfront, payments to personal accounts, or wire transfers to unfamiliar entities should be treated with extreme caution. Use payment methods that offer buyer protection whenever possible.

Building Long-Term Manufacturing Partnerships

Finding reliable clothing manufacturers in Guangzhou is only the beginning. The most successful fashion brands develop long-term manufacturing partnerships that improve over time, becoming strategic assets rather than mere transactional relationships.

Start with small test orders to validate a manufacturer’s capabilities before committing to larger production runs. This approach lets you assess actual product quality, communication effectiveness, and reliability without risking significant capital. Many manufacturers expect smaller initial orders and will offer more flexible terms for new relationships. Use this testing period to establish working procedures, build rapport with your contacts, and identify any issues that need to be addressed before scaling production. The investment in this careful approach typically pays off through fewer problems and better outcomes as the relationship matures.

Invest in clear documentation to prevent misunderstandings and protect both parties. Provide detailed tech packs that include specifications for materials, measurements, construction methods, and quality standards. Document all agreements in writing, including pricing, timelines, quality requirements, and payment terms. Establish clear procedures for change orders, quality disputes, and shipping logistics. While building a relationship, you might tolerate some informal communication, but formal documentation becomes increasingly important as order sizes grow. The best manufacturer relationships are built on clear expectations documented in writing.

Maintain regular communication even between active production runs. Check in periodically with your manufacturing partners to stay informed about their capabilities, any changes in their business, and industry developments that might affect your products. Share information about your brand’s direction and upcoming collections. This ongoing engagement builds mutual understanding and loyalty, making manufacturers more invested in your success. It also means you’re less likely to encounter surprises—either positive or negative—when you start new production runs.

Address problems constructively when they inevitably occur. Even excellent manufacturers will occasionally miss deadlines or have quality issues. How you handle these situations determines whether they become relationship-ending conflicts or opportunities to strengthen your partnership. Approach problems with specific information and constructive solutions rather than general complaints. Give manufacturers opportunity to explain and remedy issues before escalating concerns. Most problems can be resolved through direct communication and reasonable compromise. Burning bridges over minor issues rarely serves your long-term interests.

How Algo Bert Fashion Can Help

At Algo Bert Fashion, we understand the challenges fashion brands face when sourcing from Guangzhou’s manufacturing landscape. With years of experience in the local industry, we’ve developed rigorous supplier networks and quality assurance processes that help our clients avoid the pitfalls that plague less experienced importers.

Our services include complete manufacturing support—from initial supplier matching and verification to quality control and logistics coordination. We work with clothing manufacturers in Guangzhou across all product categories, matching your specific requirements with facilities that have proven capabilities. Our team conducts factory audits, manages sample development, and provides ongoing quality oversight throughout production. Whether you’re launching your first collection or looking to optimize existing production, we can help you find reliable partners and build lasting manufacturing relationships.

Our Services:

- Supplier verification and factory auditing services

- Sample development and tech pack creation

- Production monitoring and quality control

- Supply chain coordination and logistics support

- Ongoing partnership management for established clients

Learn more about our manufacturing services

FAQ: Questions About Sourcing from Guangzhou Manufacturers

What is the minimum order quantity for Guangzhou clothing manufacturers?

Minimum order quantities (MOQs) vary significantly among Guangzhou clothing manufacturers, typically ranging from 200 to 500 units per color per style for established factories. Some manufacturers offer lower MOQs of 50-100 units for emerging brands or basic garments, while premium factories catering to major brands may require 1,000+ units. Negotiating MOQs is common, especially for initial orders, but be realistic about the minimum quantities needed for manufacturers to operate profitably. Starting with factories that accommodate smaller orders allows you to test quality and reliability before committing to larger volumes.

How long does it take to produce clothing in Guangzhou?

Production timelines in Guangzhou typically range from 30 to 60 days for standard orders, depending on order complexity, quantity, and factory workload. This timeline usually includes material sourcing (5-10 days), sample approval (7-14 days), production (20-35 days), and quality control plus shipping preparation (5-10 days). Rush orders may be possible with premium pricing, but building in buffer time is always advisable. Factors that can extend timelines include custom material orders, complex embellishments, peak season demand, and holiday closures (notably Chinese New Year in January-February).

Can I visit clothing factories in Guangzhou without a visa?

No, you generally need a valid business visa to enter mainland China and visit factories in person. Tourist visas typically don’t permit business activities, including factory visits. However, you can engage a local sourcing agent or quality control company to visit factories on your behalf, providing you with detailed reports, photos, and video of facilities and production. This approach offers a practical alternative when international travel isn’t feasible, though direct visits remain ideal for major manufacturing relationships.

How do I protect my designs when working with Chinese manufacturers?

Protecting your designs in China requires a multi-layered approach. Start by having manufacturers sign Non-Disclosure Agreements (NDAs) before sharing detailed designs or tech packs. Register your designs and trademarks in China through the National Intellectual Property Administration (NIPA) for the strongest legal protection. Consider working with multiple factories for different product components to prevent any single manufacturer from having your complete design. Maintain clear documentation of your original designs with timestamps. While enforcement can be challenging, registered IP provides legal recourse if infringement occurs.

What payment terms are standard when working with Guangzhou manufacturers?

Standard payment terms for international buyers typically involve a 30% deposit to start production, with the remaining 70% due before shipment (often called “70/30” or “40/60” terms). Many manufacturers prefer wire transfers to company accounts, though platforms like Alibaba Trade Assurance and PayPal offer buyer protection for smaller orders. Letters of credit are common for larger orders ($10,000+) and provide security for both parties. Avoid manufacturers requesting unusual payment arrangements like full prepayment, payments to personal accounts, or cryptocurrency.

Conclusion

Finding reliable clothing manufacturers in Guangzhou requires research, verification, and ongoing relationship management—but the effort pays dividends in product quality, production reliability, and long-term business partnerships. By understanding the manufacturing landscape, conducting thorough verification, asking the right questions, and recognizing warning signs early, you can navigate Guangzhou’s complex supplier ecosystem with confidence. Start small, build documentation, maintain communication, and address problems constructively. With patience and persistence, you’ll find manufacturing partners who become true extensions of your brand’s success.

Ready to start your manufacturing journey? Let Algo Bert Fashion guide you through the process of finding and working with reliable clothing manufacturers in Guangzhou. Our expertise in local manufacturing and commitment to client success helps fashion brands launch and grow without the costly learning curve many experience when sourcing independently.

Contact our team for a free consultation or get started with our sourcing services

Related Posts:

- The Complete Guide to Clothing Manufacturing in China

- Guangzhou vs Shenzhen: Which is Better for Clothing Manufacturing?

- What is MOQ: Minimum Order Quantity Explained